Selecting the ideal Stability Chamber, also known as a Stability Test Chamber, is crucial for ensuring accurate testing results and maintaining compliance with industry standards. With so many options available, it’s essential to consider several key factors before making a decision. Here’s a guide to help you choose the right Stability Chamber for your business, with insights into how Labonce Stability Chambers stand out.

1. Temperature and Humidity Range

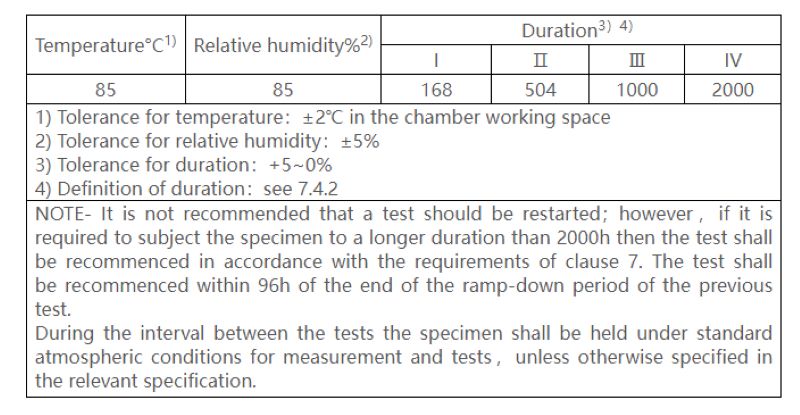

The core function of a Stability Chamber is its ability to maintain precise environmental conditions. Ensure the chamber you choose can meet your required temperature and humidity ranges. For most industries, a range of 10°C to 60°C for temperature and 20% to 95% RH for humidity is sufficient. Labonce stability chambers excel in delivering stable and uniform conditions tailored to various applications.

2. Chamber Size and Capacity

Assess your testing volume to determine the appropriate size. Smaller chambers are ideal for compact operations, while larger, walk-in models suit high-volume testing. Labonce offers a variety of sizes, from benchtop models to walk-in chambers, to fit your specific needs.

3. Compliance with Standards

In industries like pharmaceuticals, compliance with standards such as ICH Q1A is non-negotiable. Labonce Stability Test Chambers are designed to meet global regulatory requirements, ensuring reliable testing results and audit readiness.

4. Energy Efficiency

Opt for an energy-efficient chamber to reduce operational costs without compromising performance. Labonce chambers are built with energy-saving technology, making them a cost-effective choice.

5. Features and Technology

Look for advanced features such as programmable controls, real-time data logging, and remote monitoring. Labonce chambers integrate cutting-edge technology to enhance user experience and testing accuracy.

6. Reliability and Maintenance

Choose a Stability Chamber from a reputable brand known for durability and after-sales support. Labonce provides robust systems with low maintenance requirements, backed by comprehensive technical support.

Why Choose Labonce Stability Chambers?

Labonce is committed to providing high-performance Stability Test Chambers tailored to your business needs. With precise control systems, energy efficiency, and compliance with international standards, Labonce ensures reliable and efficient testing solutions.

Investing in the right Stability Chamber means better testing results and long-term operational efficiency. Trust Labonce to deliver excellence in stability testing technology.