As one of China vibrating feeders manufacturers,we are happy to share some key information about vibrating feeders with you.Vibrating feeders are usually used in the start stage of production lines and are widely used in industries such as metallurgy, coal mining, mineral processing, construction materials, chemistry, and wear-resistant materials. The BGFGF series vibrating feeder, delivers block or granular materials uniformly and continuously to the receiving equipment in the production line, which is one of key equipment to ensure high efficient and stable operation of the production line.

1.Basic specification

|

Model |

Feeder Size |

Max. Feed Size |

The length of Grizzly Bar |

Installation Angle(°) |

Amplitude |

Max. Capacity |

Motor Power |

Working Speed |

Weight |

Transport Dimension LWH |

|

BGFGF1560 |

1500*6000mm |

1000mm |

2*1250 |

5(0-10) |

8.5 |

800tph |

Electric |

500-900rpm |

depends on selected configuration |

6100*3650*2050mm |

|

BGFGF1040 |

1000*4000mm 2000*6000mm |

650mm |

1654 |

0 |

8 |

450tph |

Electric |

450-1000rpm |

depends on selected configuration |

4425*1800*1630mm |

|

BGFGF1260 |

1200*6000mm |

800mm |

2*1250 |

5(0-10) |

8.5 |

500tph |

Electric |

500-900rpm |

depends on selected configuration |

6100*3350*2050mm |

|

BGFGF1360 |

1300*6000mm |

900mm |

2*1250 |

5(0-10) |

8.5 |

600tph |

Electric |

500-900rpm |

depends on selected configuration |

6100*3450*2050mm |

|

BGFGF1860 |

1800*6000mm |

1200mm |

2*1250 |

5(0-10) |

8.5 |

1000tph |

Electric |

500-900rpm |

depends on selected configuration |

6100*4250*2150mm |

|

BGFGF2060 |

2000*6000mm |

1500mm |

2*1250 |

5(0-10) |

8.5 |

1500tph |

Electric |

500-900rpm |

depends on selected configuration |

6100*4450*2150mm |

2. Highlights and advantages

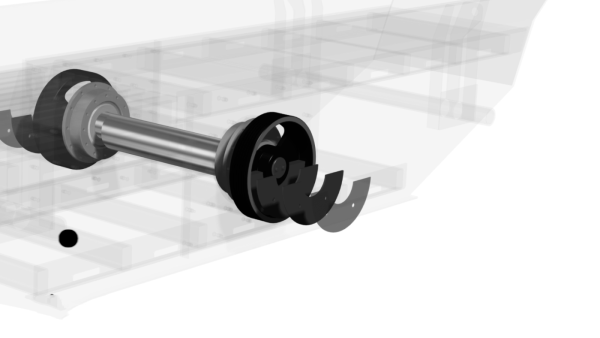

- Mature exciter design

Amplitude of multiple size Vibrating feeders is adjustable, and its structure is simple, easy to maintain. Can adjust the amplitude by adjusting the number of eccentric blocks on the eccentric shaft in daily operation, so it is flexible to adapt to different sizes of feeding materials.

- Constant right feeding rate

The optimization of the exciter position makes the amplitude of the whole feeder very uniform, while the excitation force is large and size is small.So the Vibrating Feeder machine runs stably, feeds material with a right feeding rate, and has high efficiency.

- Low noise and low grease temperature

Adopting lithium grease, filling in the middle of the bearings, the equipment gets more best and reliable lubrication, effectively reduces the grease temperature and noise, so that the bearings have a longer service life.

- Easy operation

The Vibrating feeder is easy to install and transport, can be quickly put into production, and convenient for daily operation and maintenance. The vibration frequency of the static vibrating feeder can be changed easily by adjusting the rotational speed through the frequency converter, preventing the motor from overheating, over current and overload.

For more information about Borgers' mobile screening equipment and services, please visit our official website or contact Borgers service team.